Improving the Thermal Management of the Fitlet

Oct 12, 2015Some of the properties of the passively cooled Fitlet mini PC are silent operation, reliability, freedom from maintenance, surprisingly high performance in such a small form factor and…. heat! We understand some of our Fitlet customers have been concerned about the amount of heat dissipated from the PC (which in no way affected its performance), so in response to this heat management has been improved. As a result Fitlet now runs cooler. This makes for better user experience and easier deployment in extreme conditions. Below is a break-down of the heat management aspects of Fitlet.

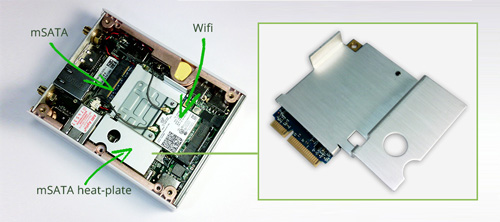

mSATA temperature

With early fitlet units there have been verified reports of high mSATA temperature. The reason was found to be heat dissipated by the mSATA module itself that was not removed effectively. A new heat-plate has been designed that conducts heat from the mSATA to the aluminium chassis. It has been found to reduce mSATA temperature by about 20°C. The mSATA heat-plate is included with any fitlet shipped from now.

If you have purchased a fitlet from us in the past and would like an mSATA heat-plate, please contact us and we will ship one to you free of charge.

CPU temperature

The CPU in fitlet is rated for 4.5W TDP (thermal design power). Fitlet is pre-configured for operating the CPU at that power level but in practice higher performance can be achieved by allowing the CPU to consume more power. This can be changed in the fitlet BIOS settings. Running the CPU at higher power will result in a higher CPU temperature and higher case temperature.

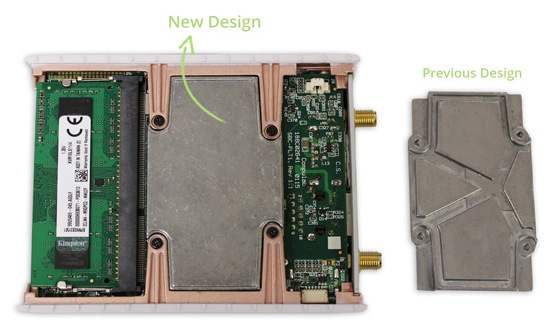

Several aspects of CPU heat dissipation have been improved for Fitlet:

1.The thermal interface material (TIM) between CPU and heat-plate has been improved using currently Arctic Silver 5 thermal paste.

2.The heat-plate has been redesigned to increase contact area between heat-plate and top cover. Users may apply thermal paste between heat-plate and top cover to further reduce CPU temperature.

3. Introduction of an optional top cover with integrated heat-sink. Fitlet heat-sink is made of extruded and machined aluminium with anodised finish. It has a much larger surface area therefore it can dissipate more heat. The heat-sink allows the fitlet to run at full TDP regardless of ambient temperature.

4. Introduction of Fitlet-H. Fitlet-H is the hardened version of Fitlet. One of its properties is a larger surface area of the all-aluminium body which allows very good heat dissipation. Fitlet-H hardware is fully compatible with other fitlet models.

Touch temperature

In passive cooling all the heat is dissipated through the case, therefore touch temperature depends mostly on the case surface area and device power. Other factors are the ambient temperature and the airflow around the device.

Fitlet, being a small passively cooled device has relatively high touch temperature under load. It is worth noting that the touch temperature does not affect fitlet safety and reliability, yet some users find high touch temperature inconvenient.

The following methods can be applied to reduce touch temperature:

1.Tune Fitlet TDP to the required performance. Fitlet is pre-configured for acceptable touch temperature. TDP can be lowered to run Fitlet cooler or increased to obtain higher performance.

2.Disable unused devices. e.g. if using wired Ethernet, WiFi can be disabled to reduce heat dissipation (and save power).

3.Consider using fitlet heat-sink. It has a dual effect – it reduces the case temperature and also reduces the contact surface with your hand to minimise inconvenience.

If you need support or any further information, we're here to help: contact us!

Part of

Part of